LENTON® Form Saver™

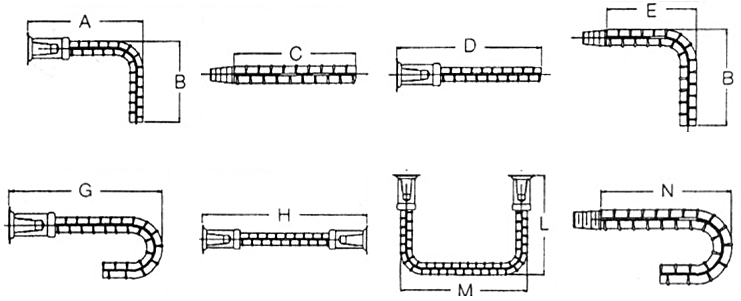

LENTON® Form Saver™ solves the age old problem of joining rebar in staged construction while protecting your valuable forms from damage.

All Form Saver™ couplers are supplied pre-assembled to the rebar with mounting plate for attachment to form work and a pressed in metal disc thread protector which can be easily removed.

Features

- Safer job site by eliminating protruding dowels

- Mounting plate has keyed holes to ease attachment to form

- Meets or exceeds requirements of most international codes and standards

- All couplers are attached to the first pour rebar

- Taper threads eliminate the problems of cross-threading while providing a precise positive locking splice

- System uses standard bar diameters

- Built in thread cover protects internal threads from concrete paste contamination and is easily removed

Applications

LENTON® Form Saver™ is ideal for slip form, jump form, segmental pour and stair well applications. They can be used to eliminate a wide variety of construction related problems:

- Pour Breaks / Construction Joints

- Slab Penetrations

- Stairwells

- Tower Crane Openings

- Future Extensions

- Dangerous Starter Bars

- Pile Extensions (cut offs)

- Beam to Columns

- Floor Slabs to Core Walls (block out)

LENTON® Taper Threaded Rebar Couplers

LENTON® is the world's most widely used mechanical rebar splicing system available today.

Features

- Unique self-aligning taper-threaded design provides continuity and structural integrity

- Spliced bars behave as continuous lengths of reinforcing steel bars by providing full strength in tension, compression and stress reversal applications

- Designed to withstand man-made blasts, and other seismic events

- Quick and easy to install

- Develops higher tensile strength than lap splicing

Provides full load transfer with the slimmest and shortest coupler possible

LENTON® Interlok™

For precast construction, ERICO offers the LENTON® InterLok™ rebar splicing system. It is designed to provide structural integrity between load bearing precast members such as columns beams and shear walls.

LENTON InterLok uses a specially formulated cementitious grout in conjunction with the LENTON taper threaded system. It offers efficient, versatile and cost-effective connections.

Features

- Convenient and flexible to use

- Eliminates unsightly and costly patchwork

- For all rebar sizes from 16 mm (#5) through 57 mm (#18)

- Optimizes production time while improving integrity of the structure

- Maintains structural integrity through precast sections - reinforcing steel acts as one continuous bar

- Tensile loads are transferred through the rebar - not dependent on the compressive strength of the concrete

- Connection is not detrimental to surrounding concrete as no heat is produced

Applications

- Taper-threaded and grouted precast construction splices

LENTON® Terminator™

The LENTON® Terminator™ is an over-sized end anchor secured to the end of a length of reinforcing steel, creating anchorage within the concrete.

This approach greatly simplifies rebar placement and reduces congestion. The LENTON Terminator incorporates the time-tested and field-proven LENTON tapered thread.

Features

- No special training required

- Eliminates rebar hook - simplifies bar placement

- Minimizes embedment lengths - reduces congestion

- Simplifies concrete placement

- Greater design flexibility

- Faster installation lowers in-place costs

- Available for standard rebar dimensions

Applications

- LENTON Terminator is ideal for all forms of construction, including dams, subways, bridges, high-rises, water treatment plants, and stadiums

- The Terminator is frequently used for Beam/Column and Roof/Column applications

- Can also be used for future extensions to Beam/Column and Roof/Column connections

CADWELD® Rebar

For the most demanding applications, CADWELD® mechanical splicing system has extremely high tensile performance. It is the only rebar splicing system that has been used in over 200 Nuclear Power Plant projects throughout the world.

The CADWELD rebar splice is a mechanical butt splice (a metal filled splice, not a welded splice) that produces a joint with basically the same mechanical properties as those of an unspliced bar. CADWELD rebar is very suitable for in-situ splicing applications.

Features

- No special skills required

- Works on all grades of steel with deformations

- Can be visually inspected

- No special bar end preparation needed

- Designed to meet or exceed many major Building Code requirements

- World’s most tested mechanical splice - over 25,000 actual tensile tests

- Consistently develops minimum ultimate strength of the rebar (150% of yield on grade 60 bars according to ASTM A615)

- Requires hand-held equipment only (no heavy hydraulic non-electrical equipment), thus can deal with minimum bar spacing

- Retrofit and repair with short dowels

Applications

- The primary usage for CADWELD is related to critical structures requiring high safety margins such as: blast resistant facilities, pressure vessel applications, seismic resistance, nuclear reactor containment structures, and in-situ splicing applications

- It is also excellent for joining circumferential bars

Quick-Wedge™

ERICO´s Quick-Wedge™ splicing system is a simple and quick alternative for joining small diameter reinforcing bars. The splice consists of an oval shaped steel sleeve and a wedge pin. Installation is made in seconds by over-lapping rebar in the steel sleeve and driving the wedge pin between the bars with a portable hydraulic hand tool.

Features

Minimizes length of exposed rebar dowel - eliminates excessive concrete chipping in retrofit installations

- Bars can be cut to the approximate size spanning between the rebar being joined

- Lightweight hand-held hydraulic pin driver designed for minimum clearance situations

- Joins #4 (12 mm), #5 (16 mm) and #6 (20 mm) reinforcing bars

- In-situ splicing with minimum dowel length requirement for bar smaller or equal to 20 mm

- Low cost

- Visual inspection possible

- Simple to use

- Connections can be made in virtually any weather

- Can make up to 100 splices per hour

Applications

Lapped bar capability and minimal exposed bar ends make the Quick-Wedge system ideal for repairs or expansions including:

- Bridge Repair

- Road Repair

- Precast

- Building Extensions

- Spiral Reinforcement

- Stirrups and Ties

- Pile Extensions

- Epoxy Coated Rebar

Speed-Sleeve™

Speed-Sleeve® is the ideal mechanical splice for compression only steel reinforcement applications. The system is designed to allow compressive loads to be transferred by aligning square cut rebar to bear on one another.

Features

- Install on rebar dowels without upper bar in place

- Fast one man installation keeps costs down

- Can be used on bundled bars

- Needs only lightweight ratchet wrench

- Positive end bearing maintained - doesn't depend on weight of rebar to keep ends in contact

- Transition splices can be made using simple adaptor inserts

- Easily removed and reused

- Self supports, no tack welding needed

- Bars can be individually secured - compensates for rebar size variation and out-of-roundness